About Us

Mahajan Malleables - Molding excellence, Casting tomorrow.

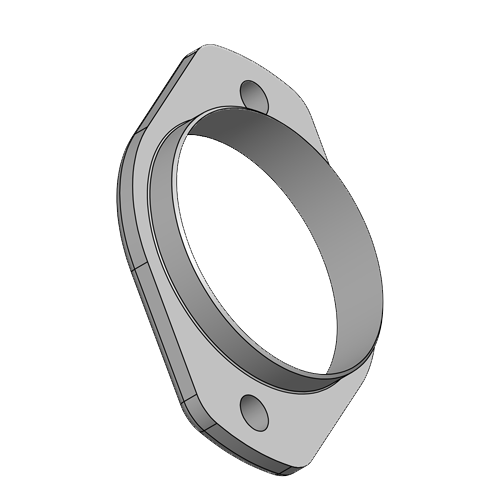

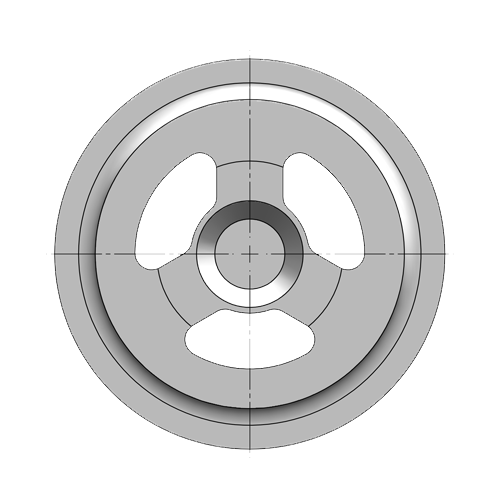

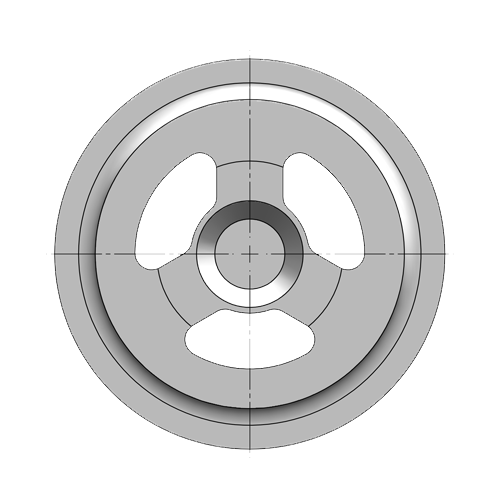

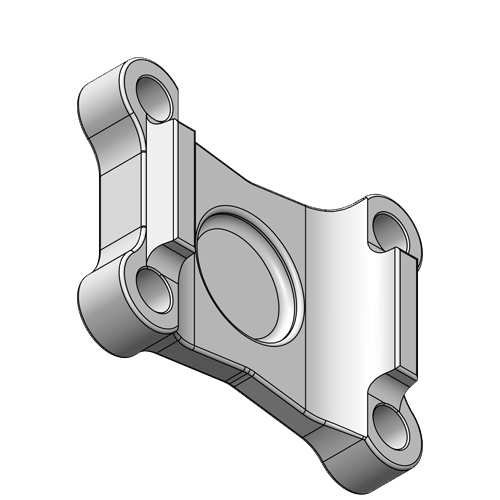

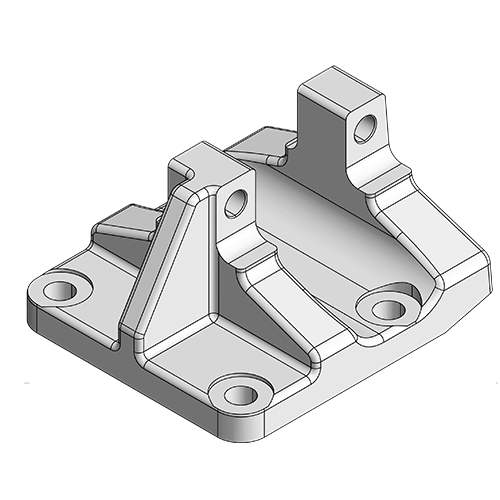

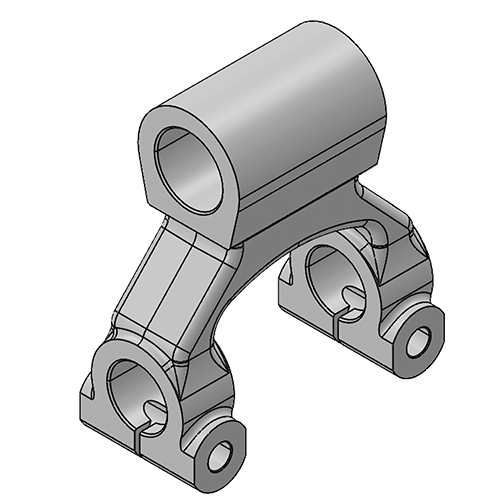

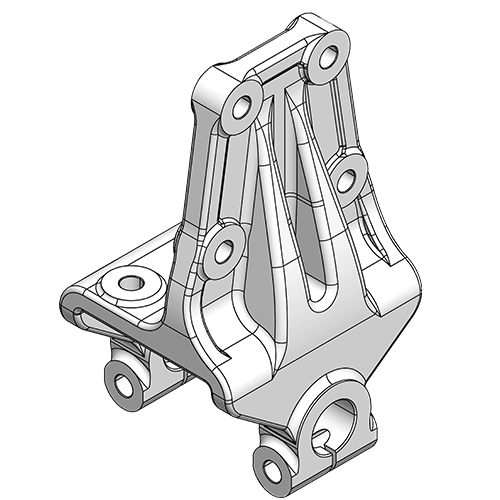

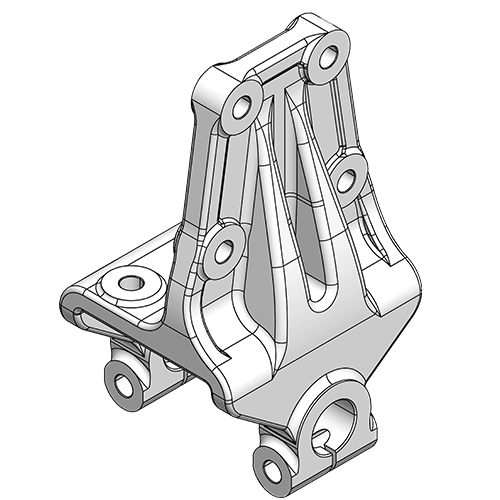

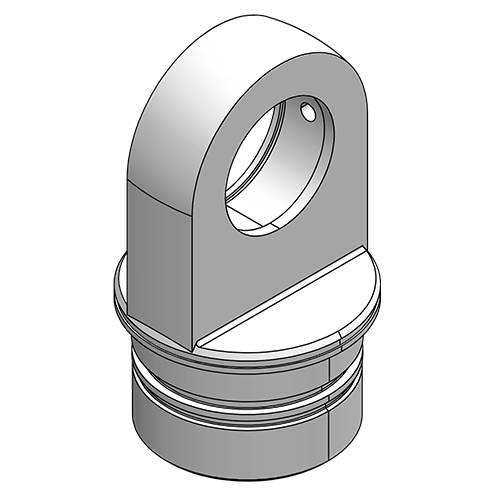

Welcome to Mahajan Malleables, your premier destination for precision casting and machining solutions. As dedicated partners in the world of casting, we specialize in C.I. and SG or Ductile Iron casting, setting new benchmarks in quality and innovation. Our Commitment: At Mahajan Malleables, precision is our promise. With a state-of-the-art facility featuring cutting-edge technology, including the Disa ARPA 300 molding machine and a spectrum of testing equipment, we ensure the utmost accuracy in every pour. Our casting capacity of over 3,000 tonnes annually speaks volumes about our dedication to delivering top-quality results.

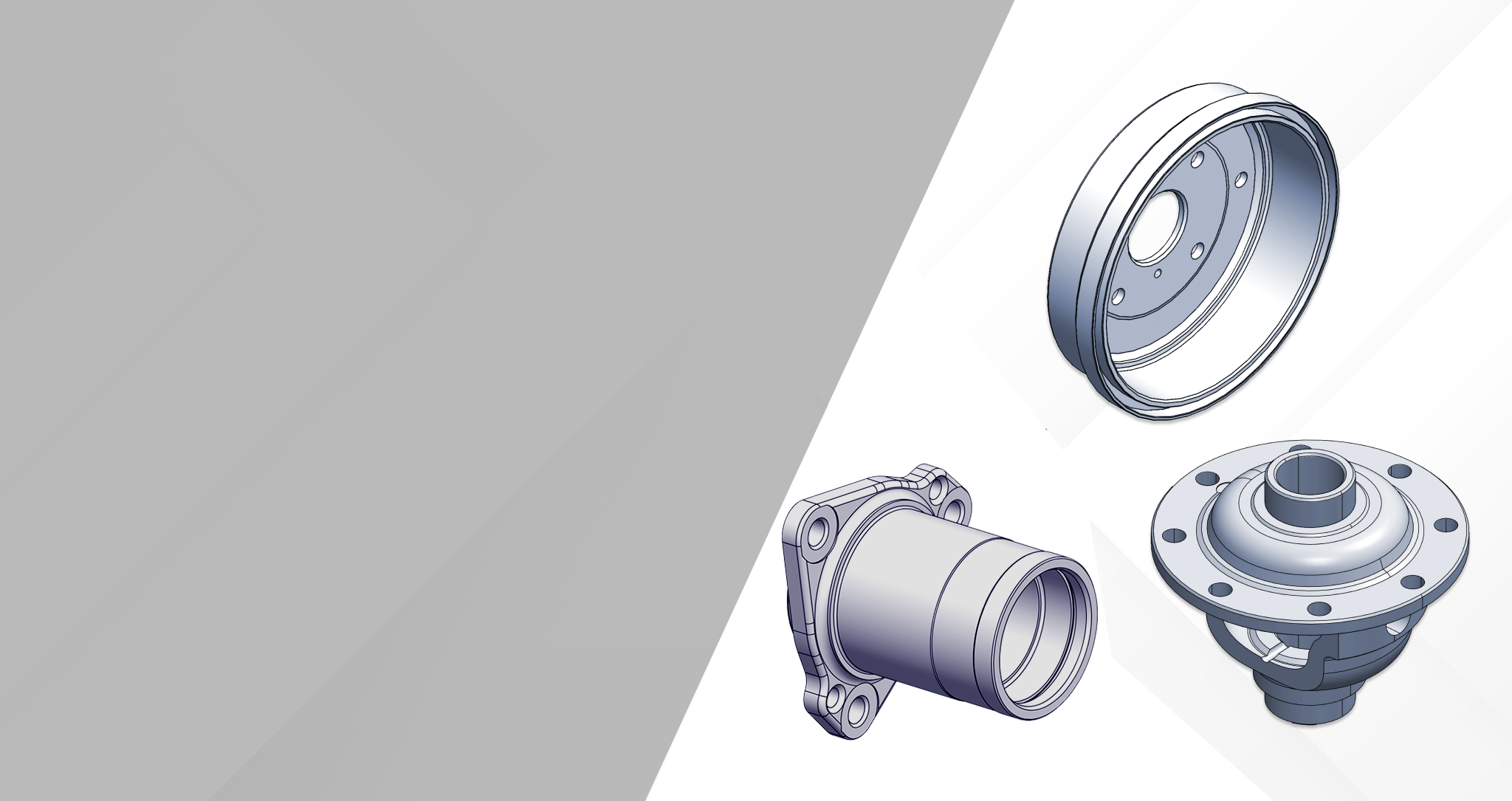

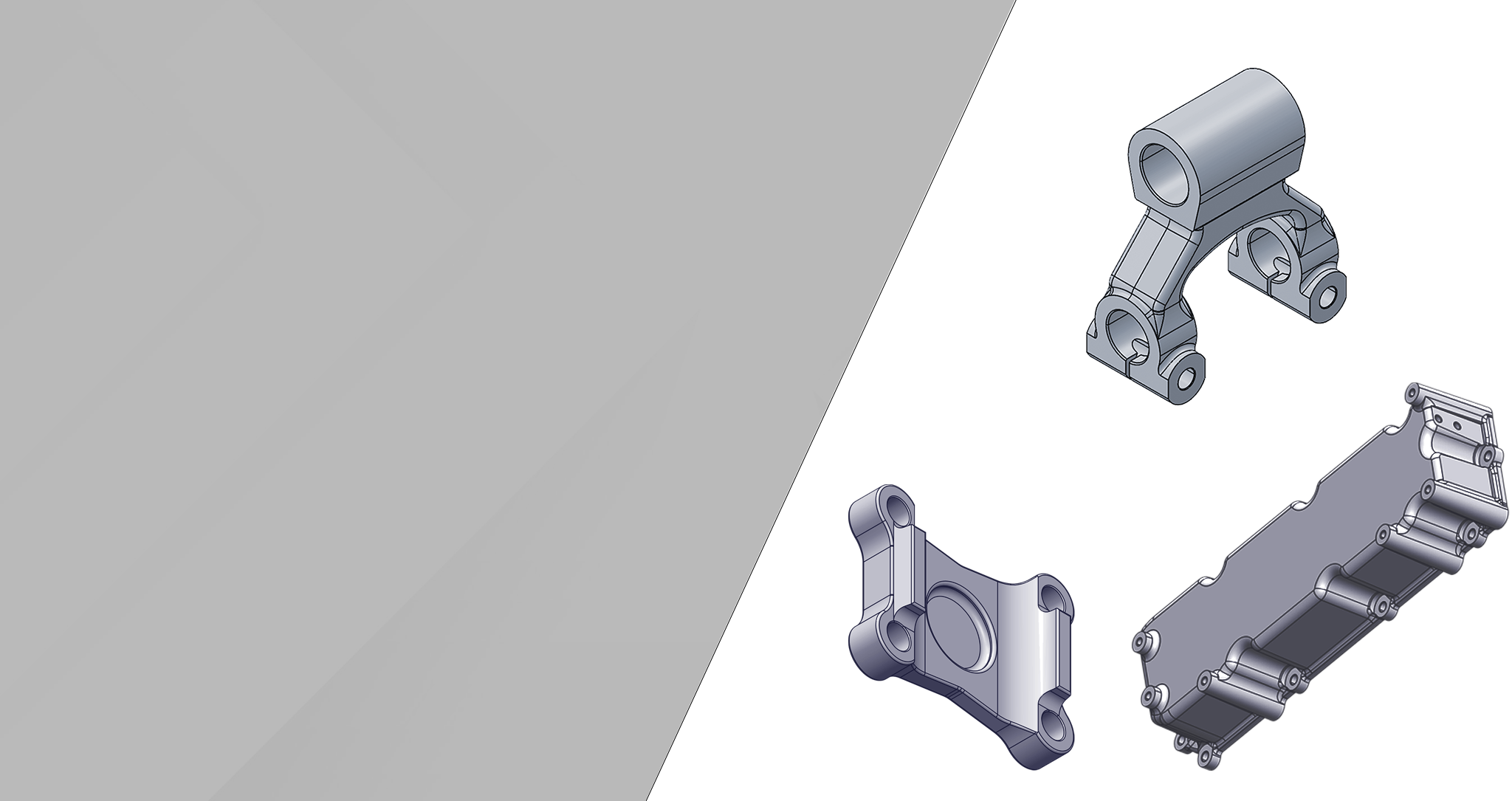

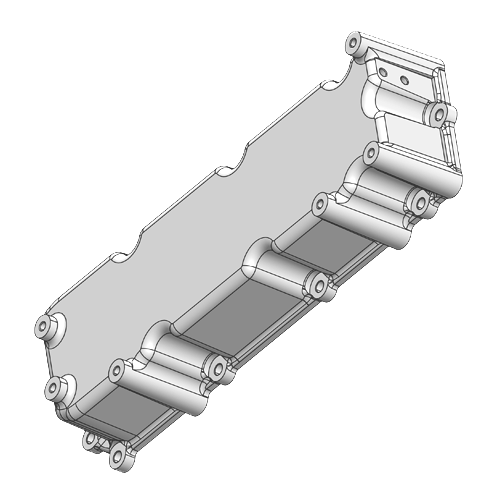

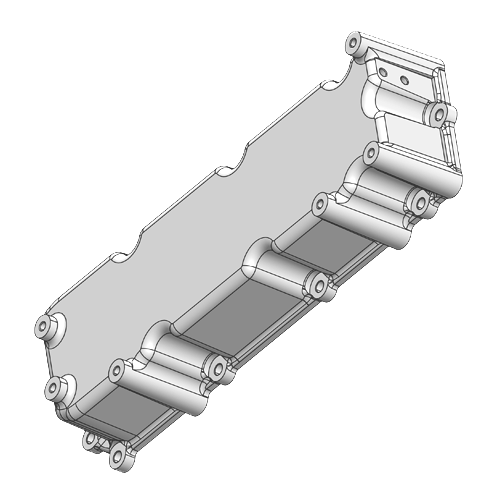

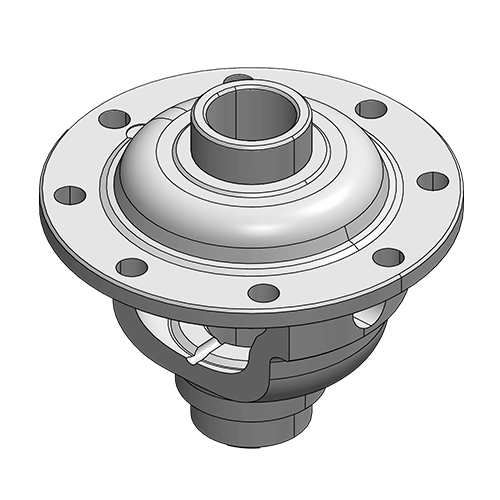

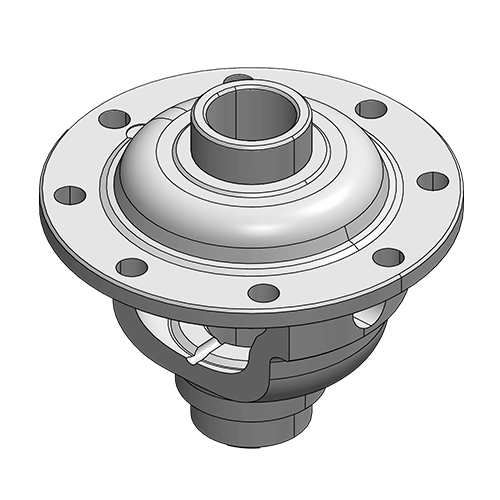

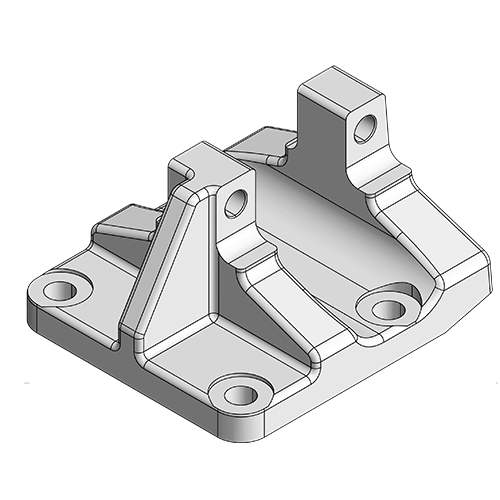

Beyond Casting: But we go beyond casting. Our journey extends to our sister concern in Agra where castings come to life through precision machining. With 60+ CNC turning and milling centers, 4-axis and 5-axis rotary tables, and advanced quality control measures, we craft components that exceed expectations. Our

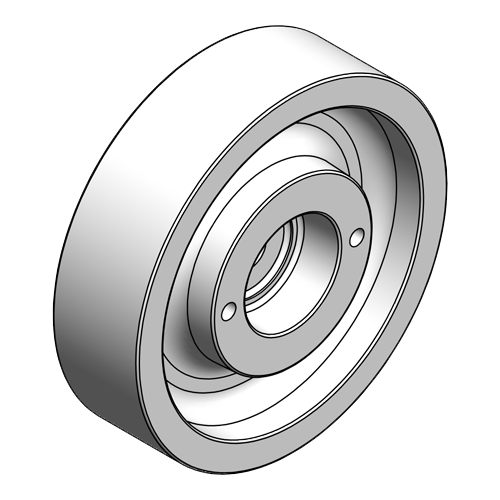

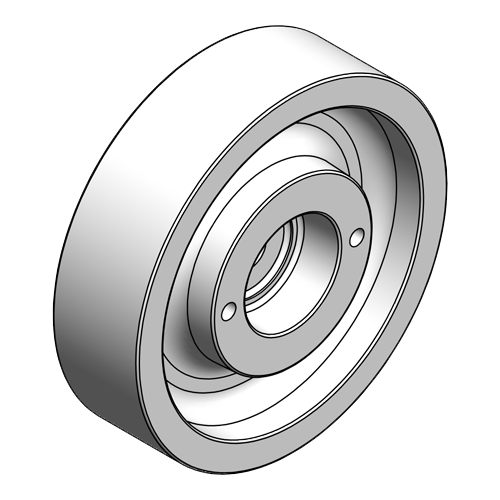

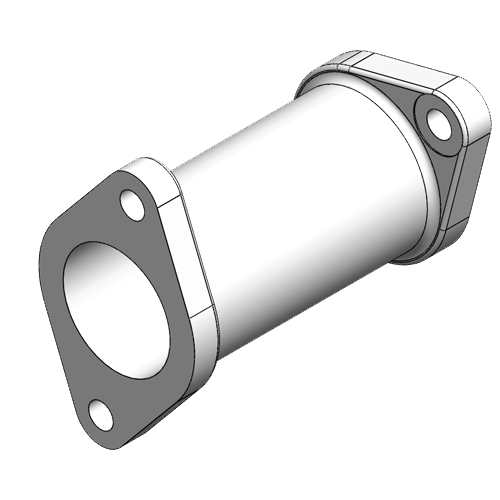

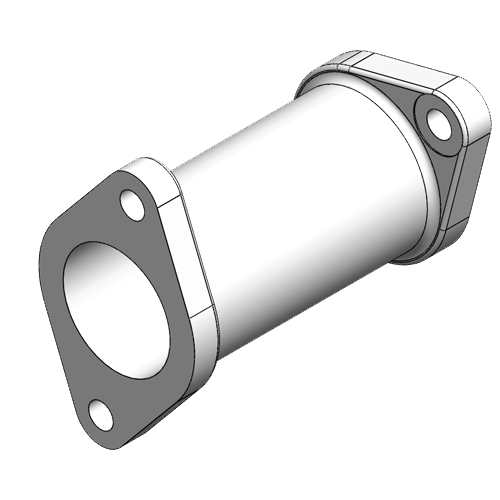

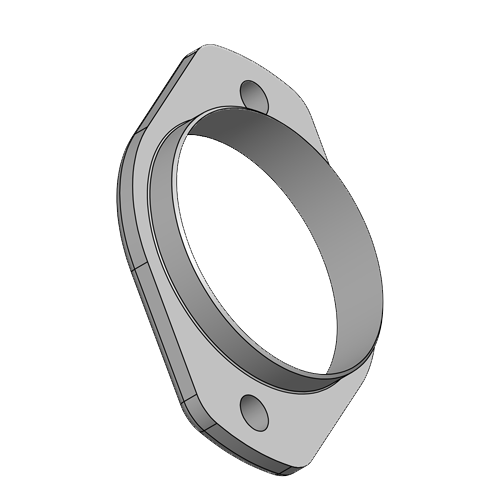

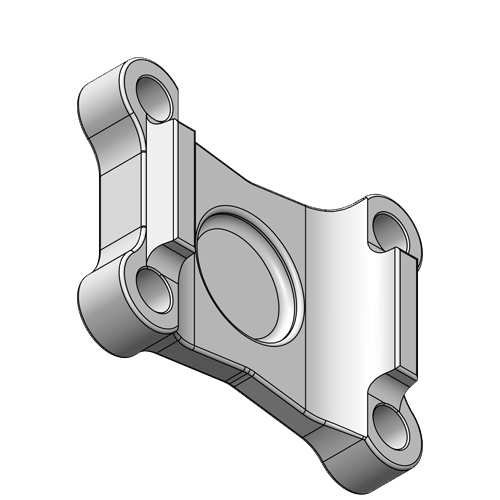

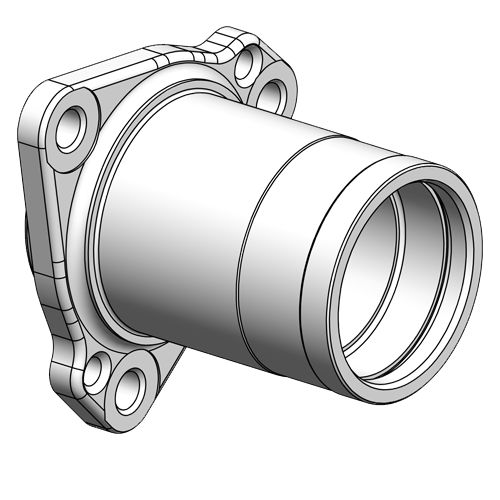

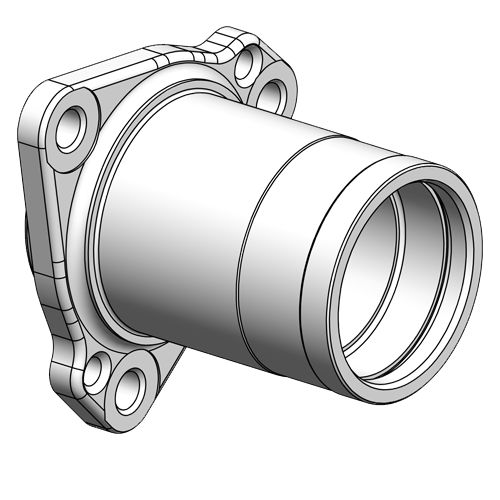

Automotive Focus: Specializing in the automotive sector, Mahajan Malleables caters to a diverse range, including passenger, commercial, and agricultural vehicles. Our expertise extends to vital subsystems such as Suspension, Braking, Engine, Differential, Pump, and more.

Join us on a journey where craftsmanship meets innovation, where every casting and component tells a story of excellence.

Why Choose Us?

Opt for Mahajan Malleables to experience a seamless transition from design to the final product. Benefit from unparalleled expertise, cutting-edge technology, and an unwavering commitment to quality. Your success is our top priority.

Our Facilities

Facility

Mold & Pattern Making

Intricate molds and casting patterns can be designed using cutting-edge CAD/CAM software, and created with precision on VMC machines to ensure accurate casting. The MMPL team has a huge experience in the casting industry and knows how to make complex casting profiles.

Green Sand Casting

Step into Mahajan Malleables' Green Sand Casting facility, where mastery meets innovation. Powered by a robust 450 kW furnace, we craft excellence in various grades such as FG200, FG250, FG260 in Cast Iron, and precision-engineered grades like 400/15, 450/10, 500/7, 600/3, 700/2, 800/2 in SG Iron. Our fusion of cutting-edge technology, including the Disa ARPA 300 molding machine, and time-honored craftsmanship results in the alchemical transformation of molten metal into meticulously graded components.

Metallurgical Testing

Ensuring precision in every cast, we employ cutting-edge technology for comprehensive metallurgical testing. Our Ametek Spectrometer and Carbon-Silicon analyzer meticulously analyze chemical compositions. To assess mechanical properties such as Tensile Strength, Hardness, and Elongation, we utilize the Universal Testing machine and BHN tester. Surface crack detection is achieved through MPI (Magnetic Particle Inspection) testing, while a Microscope is employed for detailed examination of the microstructure. This rigorous testing regimen exemplifies our commitment to delivering castings of unparalleled quality and integrity.

Shot Blasting & Fettling

Our Shot Blast process guarantees impeccable surface quality, employing precision cleanup, known as fettling. This meticulous step ensures that all components are not only flawless but also perfectly prepared for machining.

Machining

Our sister concern, Parth Engineering, has an advanced machining center that houses 60+ CNC and VMC machines with 4th and 5th axis rotary tables to deliver components for any industry requirement with unparalleled accuracy. It also houses Deep-hole drilling and Broaching machines which allows for supplying value added components to our customers.

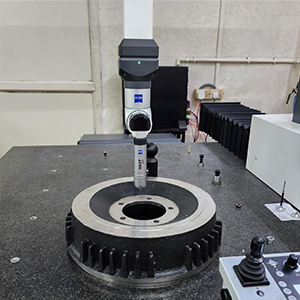

Quality Control

Our fully machined components undergo a rigorous quality control process and is the cornerstone of our operations. We are dedicated to providing our clients with first-hand, premium quality products, and we uphold our commitment to quality through a meticulous and comprehensive quality control process. Our state-of-the-art quality infrastructure includes Co-ordinate Measuring Machine, Probing systems, auto and pneumatic gauging, Contracer, Trimos, and more. When you choose MMPL, you choose excellence, reliability, and a commitment to delivering the best in the industry.

Equivalent Grades

We cast these Equivalent Grades in Cast Iron.

| IS-210 | ASTMA-48 | BS-1452 |

DIN-1691 | GOST-1412 | JIS-G5501-89 |

| FG 150 | 25B | 150 | GG-15 | C415 | FC150 |

| FG 200 | 30B | 200 | GG-20 | C420 | FC200 |

| FG 220 | 35B | 220 | - | C424 | - |

| FG 260 | 40B | 250 | GG-25 | C425 | FC250 |

| FG 300 | 45B | 300 | GG-30 | C430 | FC300 |

We cast these Equivalent Grades in SG Iron or Ductile Iron.

| IS 1865 | ASTM A536 | BS 2789 | DIN 1693 | ISO 1083 | UNF | JIS G5502 | EN 1563 | NBN 830-02 |

| SG 370/17 | 60-40-18 | 400/17 | GGG40 | 400-15 | FGE38-17 | FCD400 | EN-GJS-400-15 EN-GJS-400-18 |

FNG38-17 |

| SG 400/12 | 60-42-10 65-45-12 |

420/12 | - | 450-10 | FGE42-12 | FCD450 | EN-GJS-450-10 | FNG42-12 |

| SG 500/7 | 70-50-05 | 500/7 | GGG50 | 500-7 | FGE50-7 | FCD500 | EN-GJS-500-7 | FNG50-7 |

| SG 600/3 | 80-55-06 80-60-03 |

600/7 | GGG60 | 600-3 | FGE60-2 | FCD600 | EN-GJS-600-3 | FNG60-2 |

| SG 700/2 | 100-70-03 | 700/2 | GGG70 | 700-2 | FGE70-2 | FCD700 | EN-GJS-700-2 | FNG70-2 |

| SG 800/2 | 120-90-02 | 800/2 | GGG80 | 800-2 | FGE80-2 | FCD800 | EN-GJS-800-2 | FNG80-2 |

Our Location

- Mahajan Malleables Private Limited, G-94, RIICO Industrial Area, Ondela Road, Dholpur, Rajasthan - 328001

Business Hours:

- Monday - Saturday

- 09:00 - 18:00 hrs. (IST)